Why risk management is a shared responsibility for facility managers, engineers and contracted delivery partners

Executive summary

Clean and healthy water is fundamental to sustaining life—so, paying close attention to water quality in health and aged care settings is critical.

Bacterial growth and water-borne diseases pose a serious threat, especially in facilities used to care for society’s most vulnerable people. The mortality rate from Legionnaires’ disease in health and aged care settings is as high as 40 per cent.

But who needs to pay attention? Water Quality Risk Management Planning (WQRMP) is no longer solely the domain of the healthcare facility operator: now delivery partners have a vested interest in delivering facility healthy water systems supported by compliance documentation.

Just as holistic and individualised approaches to care are being recognised as critical to the patient experience and health outcomes—a holistic and site-specific approach to water quality management is key.

Managing water quality risks is not just about the health and safety of humans. More collaborative and effective water quality risk management also has implications and benefits in terms of Environmentally Sustainable Design (ESD), compliance, cost management, people management, and operational efficiency.

Maintaining healthy water systems requires a combination of skills and knowledge, both internal and external to a hospital or aged care facility, and for everyone to understand the risks and do their part to mitigate them.

Keep reading for more information or download the White Paper:

Factors affecting water quality risk management in healthcare

Modern design can increase contamination risks

Delivering quality care is becoming more complex, technologically-driven, and evidence-based. It’s no surprise then, that the infrastructure that supports health and aged care services is also becoming more sophisticated in its design, construction, and functionality.

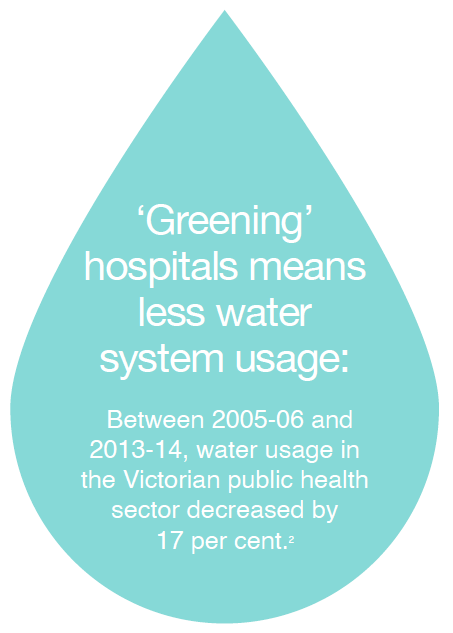

Plumbing systems in modern care facilities are becoming more complex and these facilities are facing increasing sustainability pressures. That’s why, when it comes to water systems, many contemporary approaches to design and daily operations focus on water conservation.

|

As a result, many facilities have:

While water-saving measures help health and aged care facilities adhere to It means that many hospitals and aged care facilities are harbouring water in This may result in water environments ideal for bacteria growth and |

|

Efficient water quality risk management is a sustainability issue.

Environmentally Sustainable Design (ESD) principles are not at odds with maintaining healthy water systems. It’s more accurate to say that developing better methods to control water quality risks is a neglected aspect of sustainable design.

One of the key tenets of avoiding bacterial growth in water systems is regular flushing of pipes that haven’t been used within seven days. But in a large building, how could you possibly keep track of when specific water fixtures haven’t had water flowing through them recently?

Anecdotally, the solution to this dilemma has seen facilities corral their entire workforce to participate in designated ‘flushing’ days where staff manually turn every tap on for a few minutes (‘flushing Friday’). Understandably, this unsystematic approach isn’t foolproof—and undermines water conservation efforts. Additionally it adds to a facility’s wastewater management fees, which can be considerably higher than the cost of supplied water.

Visibility of risk: the value of BIM for data-driven water systemsEngineers typically rely on building information management (BIM) systems to model and control heating, ventilation, and air-conditioning (HVAC) systems in a building, including keeping a close eye on ongoing energy consumption and air quality. Such systems are vital for green star rated buildings that must be able to prove they meet specific operating standards. However, few facilities have modelling and management software that provides live and historical data that can be used to understand and control water quality. Once pipes are laid and the Gyprock goes up, the water flowing behind the walls is often forgotten. Yet, this operational performance data is incredibly valuable for avoiding system contamination and managing flow and disinfection activities in a more coordinated, sustainable, and effective way. |

Time to get serious about planning to avoid water quality risks

Every Australian State has regulatory requirements to design, deliver and manage healthcare facilities in a way that reduces water quality risks and in particular the growth of the Legionella bacteria.

A key resource for anyone whose work impacts water distribution systems in a health or aged care facility is the enHealth Guidelines for Legionella control developed by the Australian Government. The national guideline emerged from an investigation into an outbreak of Legionnaires’ disease at The Wesley Hospital in Brisbane in 2013, as a result of contaminated water taps.

The guidelines now underpin Queensland’s mandated requirement for healthcare and residential aged care facilities to implement a water risk management plan, which is legislated under the Public Health Act 2005.

The cost of water quality incidents is highThe Wesley Hospital Legionnaires’ disease outbreak had serious public health consequences—as well as the tragic loss of life, the incident damaged the public’s trust in health services. The financial repercussions across Queensland’s health system were also severe: work to identity and treat bacterium found at facilities across the state resulted in costs ranging from $20,000 to $100,000 depending on the size of the health service.3 |

While Queensland’s experience might have been the catalyst for strong controls in that state, more and more health and aged care organisations across the country are adopting a formalised plan to meet their duty of care and stay on the front foot when it comes to compliance and proactive facilities management.

Having a plan in place, or being equipped to enable such a plan, is critical for professionals working within a healthcare or aged care facility — as well as those who consult and deliver work. This includes architects, and contracted hydraulics engineers, consultants and plumbers.

Being clear about how you manage water quality risks is critical to your capacity to:

- Be proactive, rather than reactive, in addressing water quality risks

- Meet legislative requirements to provide safe facilities and protect patients and staff

- Gain and keep the trust of your stakeholders (customers, staff, patients)

- Being able to communicate and reflect on what you’ve done, to drive improvement

How to plan for safer water systems

|

The national enHealth Guidelines for Legionella control provide a framework for implementing In recognition of the fact that managing water quality risks is a shared responsibility, the guidelines The guidelines set out a process to:

|

|

|

Importantly, the guidelines encourage not just the documentation of a plan, but regular, ongoing processes to monitor and review the effectiveness of control measures. |

Engineering, commissioning, and ongoing maintenance considerations to control water quality risks

What are the key risks in a water system?

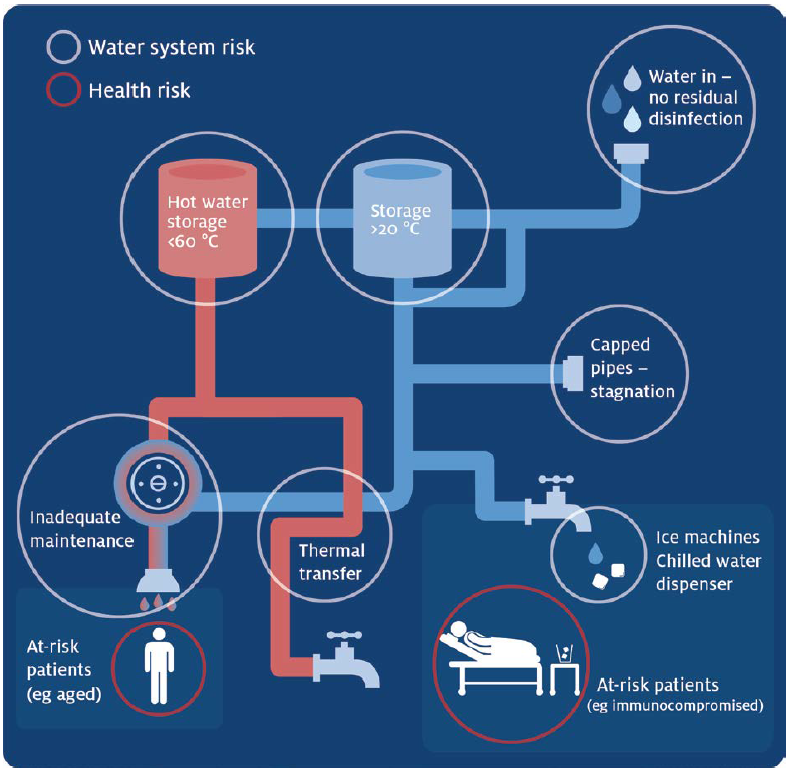

Understanding how a facility’s plumbing system is set up is an important first step in assessing risks. The following diagram from the national enHealth Guidelines for Legionella control outlines some of the typical hazards and hazardous events you should be aware of within a healthcare or residential aged care facility.1

Engineering considerations to minimise Legionella

Legionella may be present in the town water supply but, where temperatures are below 20 °C, growth is typically very slow and the concentration of Legionella is usually below the limit of detection. In a healthcare facility—where water is remaining in the system for increasingly lengthy periods of time—water temperatures within the range of 20–45 °C can create ideal conditions where Legionella is able to grow, with maximum proliferation in the range of 37–43°C.

Preventing conditions that lead to biofilm, growth of bacteria, and disease spread, all start with best-practice design of hydraulic systems. Various configurations for the design of water systems will be shaped by the type and layout of a building and its use—however, a key requirement for such systems generally is the need to incorporate a means of disinfecting and draining the system.4 The following design features are of particular importance:

- Minimising ‘dead legs’ through plumbing design: Plumbing design is changing to minimise dead legs. Poorly designed or improperly installed water systems may allow transfer of heat to cold water piping from heated water systems, other equipment, or the environment. This is especially true when the piping is within roof spaces, poorly insulated or subject to direct sunlight or other forms of external heating. Any of these situations can result in cold water temperatures greater than 20 °C, increasing the risk of Legionella growth. In warm water systems, an infrequently used fixture positioned at the end of a branch coming off the main pipe can become cool, which increases the risk of bacteria growth.4

- Avoiding water stagnation by enabling system flushing: During both the delivery and operational phases of a facility’s lifecycle, the design brief must reflect the need to manage bacterial risks in the water system. In addition to designing the installation of pipework in ways that reduces water stagnation, engineers and plumbers need to consider functional features that support system flushing for a period that is sufficient to remove all stagnant water leading to the outlet and for the operating temperature to be reached at the outlet.1 National guidelines recommend that all unused outlets be flushed every seven days at full flow.1 Enabling the disinfection of systems (typically using heat or chlorine) should bacteria be found also necessitates careful material and equipment selection

Delivery partners’ responsibilities during commissioning of water systems

If you think water quality isn’t your responsibility as a contracted delivery partner during construction and commissioning—you’re wrong! Consider the fact that during a staged delivery, water systems may be used less frequently or unused for long periods: whenever a system lies dormant you have the potential for bacterial growth.

Commissioning of water systems is an integral component of providing a safe operational system. This is recognised in the national Guidelines for Legionella control, and industry codes such as the AS/NZS 3500.1 Plumbing and Drainage Australian standard. AS/NZS 3500.1 requires that chlorination is undertaken for all new water tanks and plumbing infrastructure precommissioning, regardless of pipe diameter or water supply.1

Commissioning new buildings or new equipment comes with hazards that can increase the risk of Legionella developing. Additionally, should bacteria be detected in a new water system at the time of handover, the system will likely be a source of concern throughout its lifespan.1

Contractors engaging in commissioning works:

|

|

Questions you need to ask about your current capacity to achieve a sanitary flush

We’ve established that achieving good water quality hinges on having a water quality risk management plan, careful consideration of system design, proactive control of risks, and the capacity to respond to incidents.

However, not every water system in operation today will easily lend itself to implementing good water quality control measures. For instance, in the occurrence of a Legionella or high bacteria detection, the facility needs to have a methodology to perform a disinfection of the affected area. This may be in a ward, a floor, or an entire building.

In order for facilities managers and hydraulic engineers to practically tackle the need to ensure sanitary and disinfection flushing in a facility with traditional systems and tapware, they need to consider:

|

Will the hot waterplant provide the temperature and volume to perform a heat disinfection flush? |

Does the PPE piping support the chlorination levels required and super chlorination dosing in the event of a positive detection over periods of time? |

Will the tapware supplied help or hinder sanitation flushing: i.e., will the sensor taps open for a suitable time period? |

|

With staged and prolonged commissioning periods will tapware and valves be exposed |

Is there a better way to reduce commissioning cost and mitigate risk of bacterial growth and premature biofilms? |

What’s the best method for disinfection?By far the two most common disinfection methods are heat disinfection (also known as thermal disinfection or pasteurisation) and chlorination. Heat disinfection is fast and effective, and makes it easy to target a specific area, provided the TMV and tapware products in use are designed to facilitate this. |

Do your current fixtures support thermal disinfection?

Galvin Engineering offers a range of progressive and multi-point Thermostatic Mixing Valves (TMVs) and tapware products that can be fitted to easily allow hospitals and aged care facilities to undertake thermal disinfection of both the warm and cold side of the valve and down stream from there.

Operational Monitoring

System monitoring is essential to enacting your water quality risk management plan and meeting infection control requirements. Incorporating effective monitoring into engineering processes is the best way to mitigate water stagnation risks and adhere to compliance obligations around the prevention of Legionella outbreaks.

As discussed earlier, the challenge of ensuring systems are regularly flushed has typically required ad hoc, manual interventions that wastes the time and skill of staff and also wastes a significant volume of water — contrary to ESD principles.

You can’t manage without measuring. Operational monitoring, although not considered to be part of the Environmentally Sustainable Design (ESD) remit, will deliver significant savings in both water and energy consumption.

Regulators recognise the importance of monitoringEstablishing a monitoring program is a central part of implementing a risk management plan under the national Guidelines for Legionella control. NSW Health also recognises the benefits of system monitoring with its inclusion in the July 2016 NSW Engineering Guidelines5, which state ‘For warm water systems, the use of thermostatic mixing valves with remote monitoring is the preferred method of delivering warm water. This provides a more reliable method of controlling legionella, and will minimise the affected area in case of any issues arising.’: and as part of its Policy directory – Water – Requirements for the provision of cold and heated water6, which states that health care facility manager are responsible for ‘Ensuring that an appropriate microbial monitoring and, where necessary, a disinfection system is in place.’ |

Slash manual flushing: with precise system monitoring software

|

Adopting a targeted solution to help you closely monitor the performance of water systems is a powerful and precise way to:

Digital monitoring systems can also assist delivery contractors to demonstrate they have robust controls in place, especially for staged deliveries of projects and projects with progressive occupancy presenting typical low flow environments during the commissioning phase.

|

|

Galvin Engineering’s CliniMix® software is a user-friendly solution for monitoring with superior accuracy, that will seamlessly dovetail with water quality risk management plans implemented by health and aged care providers and delivery partners.

Our CliniMix® healthy water compliance solution lets you:

- Accurately gauge water flow and temperatures across your system: A key difference between CliniMix® and other solutions on the market is the integral Flow Switch, which measures real-time water movement and the timing of water flow to within 1 second. The solution identifies which specific valves have been used, and for how long—alerting about valves that remain unused for more than seven days so they may be flushed. There is also an automatic end of line purge option available for new builds. Plus the solution automatically captures temperature readings.

- Slash water flushing by more than 95%: Compared to a manual monitoring and testing approach, our precise digital monitoring solution typically identifies the specific valves that need to be flushed resulting in an enormous amount of water savings. Integrated temperature monitoring also saves water, as inefficient, manual efforts typically involve running taps over a thermometer.

- Easily capture, explore and report on data: Information from your water system is collected and stored without effort, so you can rest assured you have the information you need when it’s needed. Effortless record-keeping and reporting provides evidence to prove compliance and satisfy auditors. It also gives you opportunities to deep dive into your data: you can compare performance over time to track progress, revise targets, or inform operational improvements.

Water quality: a shared safety priority to support effective care

Managing a modern healthcare environment requires carefully balancing risks, costs and opportunities. Of course, healthy water is a must—given that the first priority must be maintaining the health of people using

your facilities.

But being better positioned to monitor and manage water quality risks also helps hospital and aged care facilities to address a range of organisational challenges including:

- Advancing your technology adoption and ability to make faster, data-driven decisions.

- Eliminating needless manual work, controlling labour costs.

- Reducing water wastage and wastewater management costs.

- Being on the front foot when it comes to meeting government mandates.

- More comprehensively meeting environmentally sustainable design targets.

- Reducing non role-specific demands on employees, contributing to more engaged and productive team.

- Supporting the redesign of workflows to mitigate human error, complacency and guesswork.

Creating a healthier environment and enabling water quality risk management activities is no longer solely the domain of those that maintain and operate facilities—sustaining a healthy water system throughout the life of a building is now putting pressure on the design brief and delivery partners involved in commissioning. Everybody needs to play their part to reduce and control water quality risks in health and aged care settings.

References

1 enHealth, 2015. Guidelines for Legionella control in the operation and maintenance of water distribution systems in health and aged care facilities. Australian Government, Canberra

2 Victorian Government - Hospital and health services web content, Accessed 2021 (https://www.health.vic.gov.au/planning-infrastructure/water)

3 Smith, P., 2013. Numerous Areas for Improvement Details in Review of the Prevention and Control of Legionella Pneumophila Infection in Queensland. Hospital and Healthcare website (https://www.hospitalhealth.com.au/content/clinical-services/news/numerous-areas-forimprovement-details-in-review-of-the-prevention-and-control-of-legionella-pneumophila-infectionin-queensland--1229983920)

4 Australian Building Codes Board, 2020. ABCB Handbook Warm Water Systems. Australian Government, Canberra.

5 NSW Government, 2016. NSW Health – Engineering Services Guidelines August 2016.

6 NSW Government, 2015. NSW Health Policy directory – Water – Requirements for the provision of cold and heated Water PD2015_008.