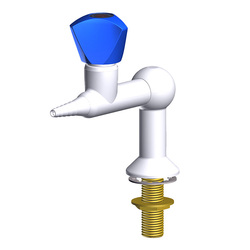

When it comes to early learning environments, the choice of tapware plays a crucial role in promoting both safety and independence among small children. Several key factors should be carefully considered to create an environment that not only facilitates learning but also prioritises the well-being of the young learners.

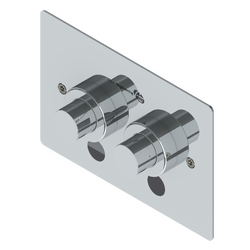

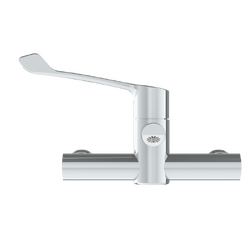

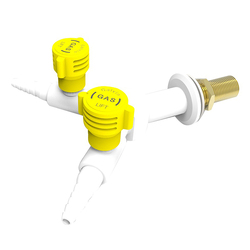

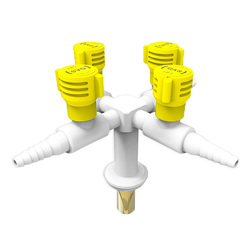

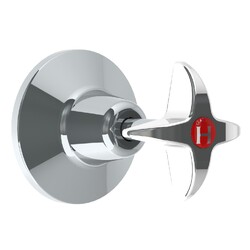

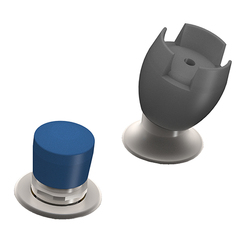

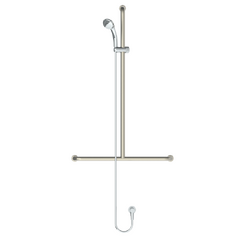

Easy operation: In early learning settings, tapware should be designed with the ergonomics of small hands in mind. Opting for handles, levers, or push buttons that are suitable for small hands is essential. Levers and push buttons are often more accessible for young children than traditional 'turn' handles, ensuring that they can effortlessly operate the tap and develop a sense of independence.

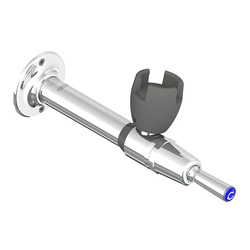

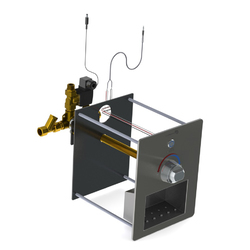

Temperature control: Incorporating tapware with features such as scald-protection and thermostatic mixing valves (TMV) to maintain a safe water temperature is imperative. These precautions help prevent accidental burns and contribute to a secure environment

Durable/safe materials: Choosing Lead Safe material ensures that tapware is free from harmful substances, meeting and exceeding state-specific standards for educational environments. This choice not only enhances safety but also ensures the durability of the fixtures in the face of constant use.

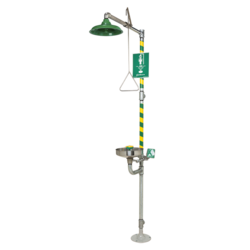

Hygiene and cleanability: Young children are more susceptible to illnesses, making hygiene a top priority in early learning spaces. Selecting tapware with smooth surfaces and minimal crevices is crucial for maintaining a hygienic environment. This design choice simplifies cleaning procedures, reducing the risk of germ transmission and supporting the overall health of both children and educators.

Installation height: To foster independence among young learners, tapware should be installed at an appropriate height, allowing children to reach the fixtures comfortably.

![Red Emperor® Fire Valve 65 BIC with Top B/Fly Cap [WA] Painted- R/Groove Inlet with Nylon Plug](/assets/thumb/381301RG.jpg?20200704030659)

![Red Emperor® Fire Valve 65 BIC withTop B/Fly Cap [WA] Painted - BSP Inlet with Nylon Plug](/assets/thumb/381301.jpg?20200704030647)

![WA/NT Firemain Booster & Hydrant Set 100TE [No Suction Riser] with Cabinet (Painted)](/assets/thumb/380121.jpg?20221209115414)

![WA/NT Firemain Booster & Hydrant Set 150TE [No Suction Riser] with Cabinet (Painted)](/assets/thumb/380139.jpg?20221209115541)